New fluid patterning approach enables programmable micro patterning and device fabrication

By : Admin -

Huang Z, Yang Q, Su M, et al. AGeneral Approach for Fluid Patterning and Application in FabricatingMicrodevices[J]. Advanced Materials, 2018: 1802172.

https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.201802172

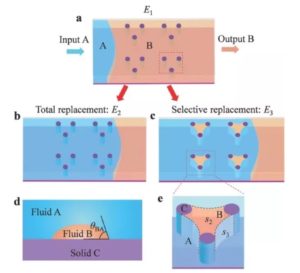

However, previous studies based on microfluidics are mainly focused on the free flow of fluid interfaces, so it is difficult to control the fluid interface due to the fluidity of the fluid interface. In fact, fixed and patterned fluid interfaces are more important in many fields, such as molecular diffusion, interfacial reactions, detection and sensing, as it provides a stable platform for observation, recognition and labeling. In addition, the graphical gas-liquid interface can be used as a soft template for assembly and printing of functional materials.

On the surface of the solid, it is an effective way to form a fluid in another immiscible fluid, which is an effective way to form the interface of the patterned fluid, which has aroused wide attention in different fields of research.

For example, a patterned bubble is formed in the water as a template for material assembly, forming a patterned droplet in the air for liquid operation, and forming a patterned oil droplet in the water or a patterned drop in the oil on the solid surface through a solvent. However, creating and accurately controlling the fluid pattern of different materials is still a huge challenge.

The research group of Professor Song Yanlin of the Chinese Academy of Sciences has recently reported a general method for creating patterned fluid interfaces in microchannels.

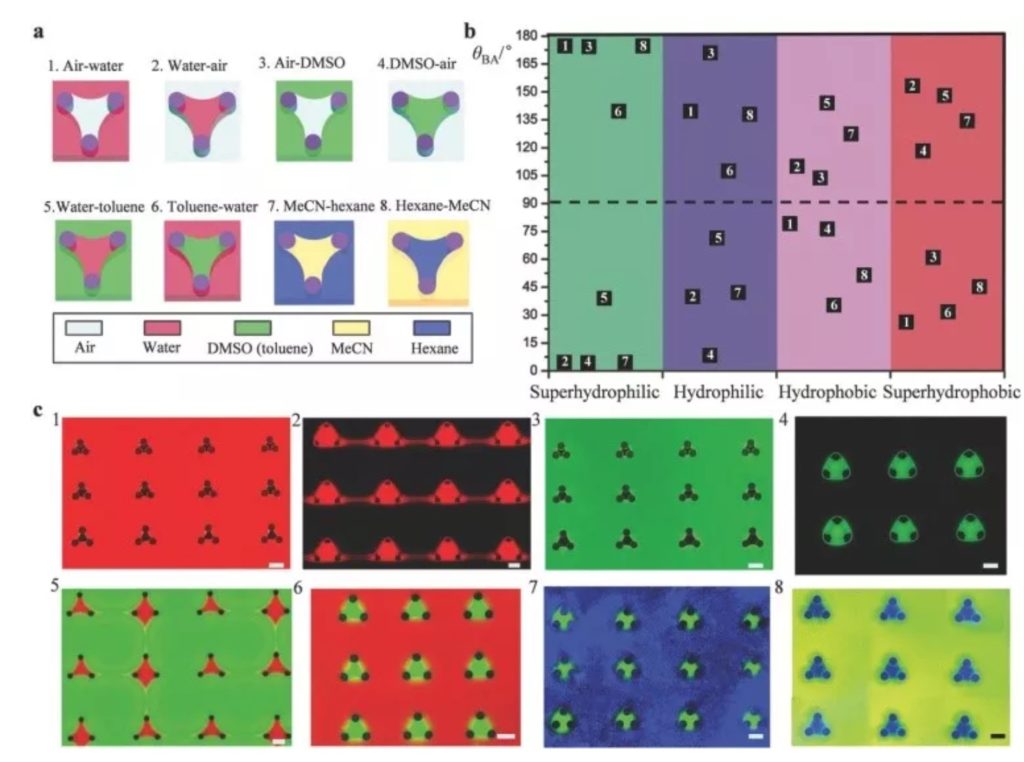

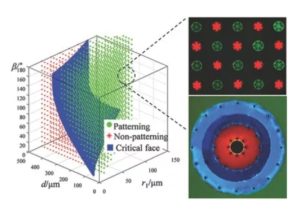

For the preparation of fluid patterns, the wettability and geometry of the microcolumn are the two most critical factors. The study proposed their respective design principles. In theory, in theory, for any non mixed fluid of fluid A and fluid B, it is assumed that theta BA is the contact angle of the fluid B on the surface of the microcolumn in the fluid A, and if θBA<90°, the fluid B can form a pattern in the fluid A under the action of the microcolumn.

In experiment, this rule is applicable to dozens of immiscible fluids, which consist of more than twenty kinds of common fluids, including air, water and oil. In addition, the shape, size and position of the fluid pattern can be well controlled by designing the geometry of the micro column template reasonably. Combining the design of wettability and geometry with continuous fluid replacement technology, the programmable multiphase fluid model can be realized.

This general principle and method of fluid patterning provides a promising platform for the study of the basic processes on the fluid interface, which enables multiphase fluids to achieve programmable patterning and multi-functional materials to assemble micro optoelectronic devices.